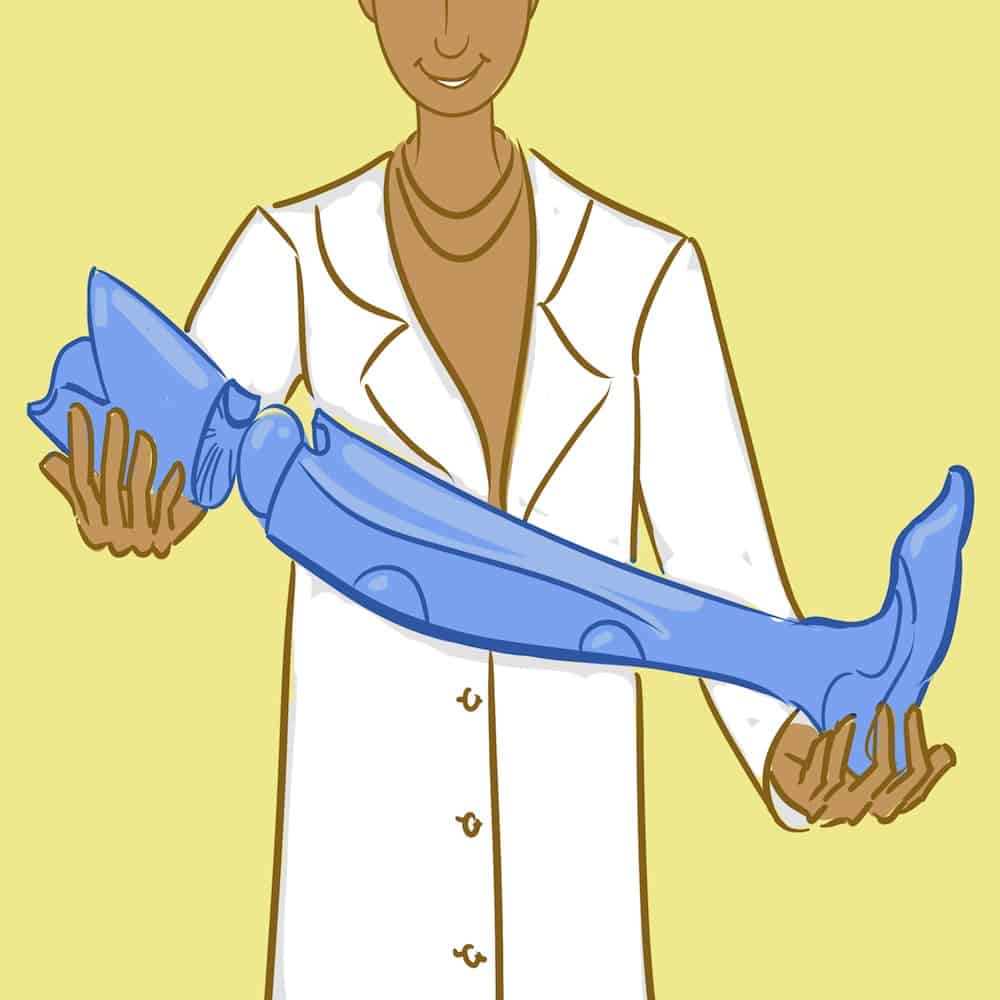

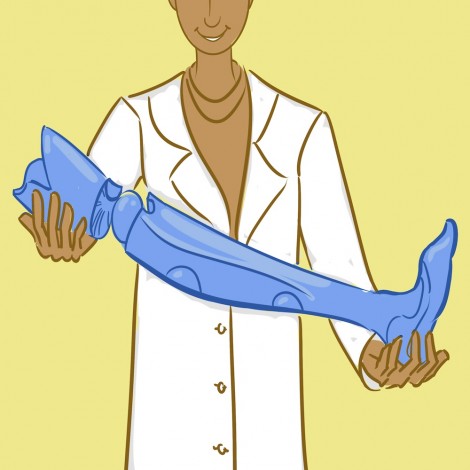

Critical Making Lab, part of the University of Toronto’s Faculty of Information, has developed 3D-printed sockets for prosthetic limbs. These limbs will be used by CoRSU, a hospital in Uganda, as part of a partnership with international non-governmental organization cbm Canada.

NANCY JI/THE VARSITY

“We’re only making the socket, because those are actually customized. The socket is the most time-consuming part of the process,” explained ginger coons, a PhD student working at the lab. “We use the process which is supplied by the Red Cross, who have books and guidelines for how to make a prosthetic limb. They are also the supply chain that gets all the supplies through,” said coons.

The program currently suffers from a lack of prosthetic technicians available in the developing world. According to coons, the World Health Organization estimates that there are only 50,000 technicians in the developing world, which it considers insufficient.

The lab has been using 3D printing since 2009, according to the its head Matt Ratto, a U of T professor with the Faculty of Information. Critical Making Lab also received attention earlier this year for printing a “Liberator” 3D-printed handgun. Ratto notes that the process of making a prosthetic limb is effectively similar, and both products have the same implications.

Both Ratto and coons describe Critical Making Lab a social science laboratory whose focus is on the social effects of technology. When asked about the effects of 3D printing in the next 10 to 20 years, Ratto said that he sees promise, but also that the technology has limits: “There’s this idea that some people have that you can have a 3D printer in your home, and you can print out Tupperware instead of buying it from the dollar store. But it’s overkill to get mass produced products through a 3D printer, because injection molding is so inexpensive. The only way you’d use a 3D printer is for something very specialized. A cell phone cover made specifically for your phone, for example, or a replacement knob to a door from the 1940s, customized objects.”

“Even if in the future there were drastic improvements to the technology, 3D printing is better for one object than for a million. Sometimes you can use injection molding in 3D printing. But the predictions are comparable to when people said that online digital printers would be replacing paper.”

This article has been revised to reflect the following corrections: ginger coons’ name was incorrectly capitalized; cbm Canada and CoRSU were referred to using incorrect terms; and inaccurate information was included regarding the process by which the printed limbs are designed and produced.