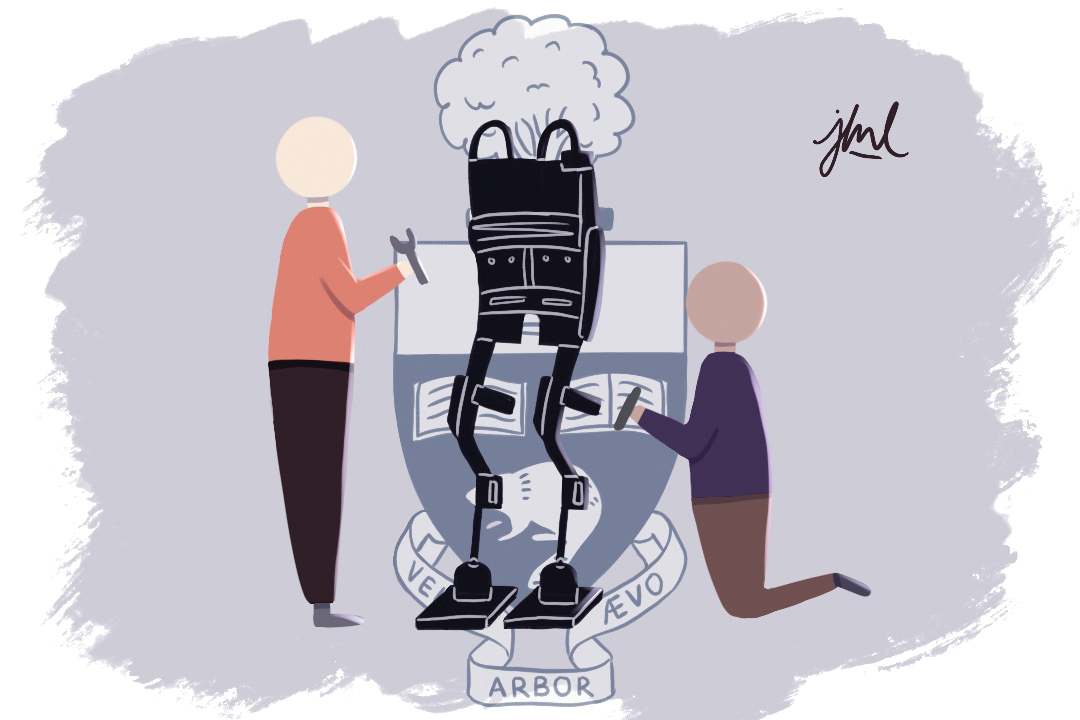

The University of Toronto Design League’s (UTDL) third Designathon was held February 4–6, where over 100 people from around the globe participated. University students from different backgrounds were invited to design a neurologically controlled exoskeleton.

In the 47-hour sprint held online this year, recent high school graduates, PhD candidates, and anyone in between competed with each other. The Designathon offers opportunities for students over a wide range of levels and fields to accomplish hands-on design projects. All students — even those in fields like political science with no prior design experience — participated in the event.

Where it all started

The Varsity spoke with Kyle Damrell, currently the chief technology officer of the UTDL and one of its founders. Damrell highlighted his working objective of translating “the digital workspace [into] physical [ones].”

Much of the mechanical engineering coursework that Damrell did throughout his undergraduate studies focused primarily on learning theory. For example, one of his class’ efforts to collectively model a gearbox and simulate stress points involved virtually no production of the gearbox, nor were there any consideration of the real-life applications of such a project. Having a rich history with 3D printing and CAD software dating back to grade 10, Damrell wished to bridge the gap between theoretical comprehension and practical application of engineering skills.

Jump straight into the action

The mechanical components of UTDL’s exoskeleton are designed to assist the function of the ankle to improve the mobility of patients with neurodegenerative diseases. The end product includes a motor that powers a simple joint with one point of independent motion.

Many teams of students collaborated to bring the project from conception to completion. There is a software team working with electroencephologram (EEG) signals from the brain to control the exoskeleton’s motor and stimulate muscles. When the prototype is 3D printed and assembled, a combined team of 11 people — some even exposed to 3D modelling for the first time — will move on to software and hardware testing. However, the design team has not yet met with end users of their product — instead, they are opting to build a functional device first.

Success stories

It is notable how one of the winning teams had a high school student — a perfect demonstration of the openness of design engineering projects to all. As the UTDL grows, new students with unique and diverse backgrounds can help define engineering goals and implement more human-centered design.

Ella Walsh, an undergraduate student at the University of Waterloo studying biomedical engineering, explained how “non-mechanical engineering students, perspectives from different fields, is what makes a design team really successful.”

As the project manager for the exoskeleton, Walsh was excited when she interviewed Amy Guo, a University of Toronto undergraduate political science student. As a member of the mechanical design team for the exoskeleton, she said that “[Guo] really wanted to join a design club [because] this is something [that she has] never done before.” Guo has enjoyed the steep learning curve of design thinking and CAD software. She is currently working on a 3D-printed electronics enclosure.

Tochi Oramasionwu, a U of T master’s student who is also the exoskeleton’s mechanical team lead, expressed how “it’s important to have a solid reason why we’re doing this project.” The team may use Autodesk’s generative design feature on the enclosure, Walsh mentioned, a feature which is used more in industry than in engineering coursework. This is another way of exposing team members to novel applications and furthering Damrell’s goal of bridging the gap between theory and practice.